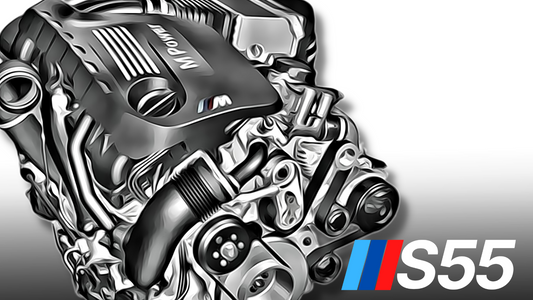

The S55 was a significant departure from the engines that traditionally powered a BMW M cars and replaced the final BMW M-car with a naturally aspirated V8 engine. The S55 debuted in 2013 and was the first mass-produced M Division engine with a turbocharger.

Introduction

The S55 was a significant departure from the engines that traditionally powered a BMW M cars and replaced the final BMW M-car with a naturally aspirated V8 engine. The S55 debuted in 2013 and was the first mass-produced M Division engine with a turbocharger.

However, devotees had nothing to complain about because the S55 was a fantastic engine and a good basis for the forced-induction engines that would likely power the M vehicles in the near future. Here's all you need to know about the BMW S55.

BMW S55 VS N55

The S55 engine is a more powerful variant of BMW's N55 engine. The N55 debuted in 2009 on the F07 5 Series Gran Turismo as the German manufacturer's first mass-produced engine with a twin-scroll turbocharger. BMW launched the S55 engine in late 2013 on the F80 M3 and F82 M4, and the engine finally made its way onto the F87 M2 Competition/CS.

Despite being based on the N55, the S55 has few similarities. Yes, the 84 mm bore, 89.6 mm stroke, and 2,979 cc displacement are identical, but the two engines couldn't be more unlike in terms of construction.

To begin, the two engines have different turbochargers: the N55 has a single twin-scroll turbocharger—the exhaust housing is divided into two "scrolls"—while the S55 has two turbochargers.

Other improvements over the N55 include a closed-deck engine block, a reworked cooling system, and lighter and stronger engine parts, which we'll go over in more detail below.

The S55 Technology

As previously stated, one of the most noticeable distinctions between the S55 and the N55 on which it is based is the adoption of a closed-deck crankcase design. The primary advantage over an open-deck design is increased stiffness, which allows for greater cylinder pressures and, as a result, more power production.

The cylinder bores also have a twin-wire arc-sprayed coating, which is an atomized spray of metal that is more sophisticated but lighter than traditional cylinder liners. The pistons themselves are comprised of a friction-reducing Grafal-coated aluminum alloy. Finally, ventilation holes in the crankcase's bottom connect two sets of three cylinders for optimal pressure equalization.

Engine Oil Supply and Cooling

Every high-performance engine requires an outstanding heat-management system to function properly. BMW employed a low-weight magnesium oil sump with a special cover that prevents low flow during extreme cornering; this ensures that the engine is never starved of fuel, even while the car is under intense lateral acceleration.

Similarly, an oil extraction pump maintains steady oil flow even while accelerating and decelerating rapidly. These systems maintain an unbroken flow of oil around the engine, allowing it to function as efficiently as possible.

M GmbH engineers also created a cooling system that contains a primary radiator as well as an extra radiator for the low- and high-temperature circuits. BMW has also fitted the S55 with an electronic water cooling pump, which aids in the temperature regulation of specific components such as the turbocharger and transmission.

Performance

In addition to the twin-scroll turbocharger, the S55 used the manufacturer's 'Valvetronic' and 'Double-VANOS' valve timing and valve lift technology, which allowed for linear power delivery over the rev range.

Throughout its life, the S55 went through several revisions. Peak power fluctuated from 275 horsepower to 493 hp depending on the car it was powering - the former is still in production on the F87 M2 CS Racing. These incarnations are distinguished by a meaty rev-band (that extends beyond 7,500 rpm) that provides an ideal mix between low-end torque and high-revving power delivery.

The previous iteration of the M3 was powered by a V8. The smaller S55 generated greater power and almost 30% more torque in its most powerful configuration, owing partly to the new twin-scroll turbo arrangement.

BMW S55 VS S58

The S55 engine was replaced by the S58 engine in 2020. The S58 is based on the B58TU engine and shares the same 3.0 liter, inline-six, twin-turbocharged architecture as the S55. However, there are some differences between the two in terms of performance and dependability.

Right away, you should be aware that the S58 has the superior engine. It's more remarkable on paper, and that performance transfers flawlessly into practice. However, if you want to tweak your engine, the S55 has more to offer. The S58 is still a young engine, and we believe it will be some time before you can tweak it as much as you can the S55.

The same may be said for the engine's dependability. Given how new the S58 is, it's too early to tell if the engine will cause problems down the road. However, because most of the internals on the S58 are identical to those on the S55, many of the S55's issues — which we'll discuss below — are likely to be carried over to the S58.

What BMWs Have The S55 Engine?

The S55 is available on a variety of recent BMWs, including the F87 M2, F80 M3, and F82/F83 M4. Higher-spec variations of this engine with higher power were available with the Competition packages of the automobiles mentioned above.

What Are The Most Common BMW S55 Engine Problems?

The S55, like any other engine, had certain common issues that M2, M3, and M4 owners reported.

Crank Hub Issues

The crank hub is one of the most serious but seldom mentioned problems with the M4. The N55, on which the S55 is based, has an extremely seldom spun crank hub. In fact, the issue did make its way onto the S55.

However, this is a very unusual condition and is unlikely to occur on a car that is only a few years old. A spinning crank hub can also cause additional engine difficulties that you should be able to detect; it will impair engine timing, put your M4 into limp mode, and almost certainly illuminate the malfunction light.

Valve Cover Gasket Oil Leaks

This issue, like the N55's, arises from comparable issues. However, this happens over time when the rubber valve gasket wears out and cracks. The plastic valve covers are also prone to breaking over time due to the high temperatures they are subjected to.

Changing the components at regular intervals is an easy approach to avoid this problem. Some owners report leaks as early as 60,000 miles, but with appropriate care, you should reach close to 100,000 miles before you need to replace the oil.

Oil Pan Gasket Leaks

Another component carried over from the N55 is the oil pan gasket on the S55. Again, it is prone to deterioration and cracking with time. The gasket on most BMW engines lasts for more than 100,000 kilometers. There have been instances of the N55 failing significantly sooner, leading us to suspect that the S55 may suffer the same fate.

This isn't as well covered as the oil spill we discussed before, but it's something you should be aware of. If you're buying a secondhand M3 or M4, see if the oil pan gasket has recently been changed.

Changing the gasket necessitates the removal of the subframe, which is a time-consuming and costly operation that you should attempt to avoid.

BMWs S55 Engine FAQs

What is the difference between an S55 stage 1 and stage 3 head?

The differences between an S55 Stage 1 and Stage 3 head primarily relate to the extent of modifications made to the cylinder head, focusing on airflow, durability, and performance improvements. Here's a breakdown:

Stage 1 Head (S55):- Mild Porting: A Stage 1 head typically undergoes mild porting, which involves smoothing and slightly enlarging the intake and exhaust ports to improve airflow. The modifications are relatively conservative and are intended to enhance efficiency and performance without major alterations.

- Valve Work: Valve seats might be reconditioned, and sometimes slightly larger or more efficient valves are installed, but usually within the OEM specifications.

- Durability Enhancements: Some reinforcement of the head might be done, but the overall structure remains close to the factory specifications.

- Application: Stage 1 heads are often used for mild performance upgrades, where the vehicle remains close to its stock power levels, but with improvements in efficiency and reliability.

- Aggressive Porting: A Stage 3 head involves extensive porting and polishing, with significant enlargement of the intake and exhaust ports. This modification maximizes airflow and is designed for high-performance applications, often paired with other major engine upgrades.

- Upgraded Valves and Springs: Stage 3 heads usually feature much larger, stronger valves, and high-performance valve springs that can handle higher RPMs and increased boost pressures. The valve guides and seats are also upgraded to support the increased airflow and performance.

- Structural Reinforcement: The head is often reinforced to handle the additional stress from high-performance setups, which might include more aggressive camshafts and higher boost pressures. This could involve stronger materials or additional machining.

- Application: Stage 3 heads are typically used in highly modified engines where significant power gains are expected. These heads are designed for high horsepower applications, often in competitive motorsports or heavily tuned street cars.